Texture Stock – Elevate Your Packaging with Style and Substance

At PackCrafted, we believe packaging is more than just a box – it’s a tactile experience that connects your brand to your customer. Our Texture Stock materials are specially selected for brands that want to stand out with a look and feel that reflects sophistication, quality, and uniqueness.

🧵 What is Texture Stock?

Texture stock refers to premium paperboard or cardboard materials that feature distinctive surface textures. From soft-touch suede finishes to linen or embossed patterns, these materials don’t just look elegant—they feel elegant.

Whether you’re creating custom candle boxes, luxury gift packaging, or boutique retail boxes, textured stock adds that extra layer of sensory appeal that sets your packaging apart.

🌟 Why Choose Textured Stock for Your Packaging?

Choosing textured stock offers a range of branding and tactile benefits:

- Premium Look & Feel – Communicates luxury, elegance, and exclusivity.

- Enhanced Customer Experience – Adds a physical, sensory layer to the unboxing experience.

- Custom Finishes – Pairs beautifully with foil stamping, embossing, and spot UV.

- Durability – High-quality textured stock offers strength without compromising on style.

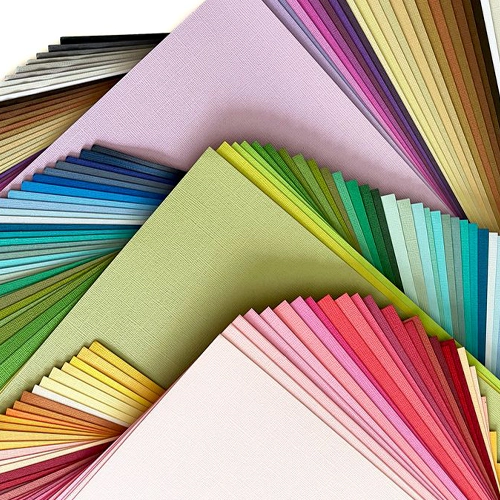

🎨 Popular Texture Stock Finishes We Offer

At PackCrafted, we carry a variety of texture stocks to match your brand’s aesthetic. Some of our most requested options include:

- Linen Textured Stock – Elegant crosshatched finish, perfect for luxury boxes

- Soft Touch / Velvet Stock – Smooth, suede-like finish that feels upscale

- Embossed Patterns – Add depth and dimension to your box surfaces

- Recycled Kraft Texture – Eco-conscious with a natural, organic texture

- Leatherette or Faux Leather Finish – Adds a bold, tactile luxury feel

If you’re unsure which texture is right for your packaging, our expert design team is here to help you choose and prototype the perfect match.

📦 Ideal Use Cases for Texture Stock

Texture stock materials are perfect for brands that want to impress, especially in industries where first impressions matter. Popular industries include:

- Cosmetics & Skincare Packaging

- Luxury Candles and Fragrances

- Jewelry & Apparel Boxes

- Corporate Gifting

- High-End Food Packaging (Chocolates, Teas, etc.)

🛠️ Customization Options Available

You can fully customize your textured packaging with:

- Full-color printing

- Foil stamping (gold, silver, holographic)

- Embossing or debossing

- Magnetic closures, ribbon ties, and more

- Custom inserts for product protection

We combine texture with creativity to build packaging that makes your product unforgettable.

🌱 Eco-Friendly Texture Options

We understand the importance of sustainability. That’s why PackCrafted offers eco-conscious textured stock options, including FSC®-certified papers, recycled textured kraft, and soy-based inks. You can go green without compromising style or feel.

📩 Get a Free Quote Today

Want to feel the difference textured stock makes? Let’s bring your vision to life with samples and custom mockups.

👉 Request a Quote or speak with our team today to get started

🔗 Explore More Materials

Looking for something specific? Discover our full range of custom packaging materials or explore:

- Rigid Box Material

- Kraft Packaging

- Luxury Foil Finishes (coming soon)

🖐️ Feel the Difference with PackCrafted Texture Stock

At PackCrafted, we don’t just create boxes – we create experiences. Let your packaging speak volumes before your product is even opened. With our wide range of texture stocks, you’re only a touch away from unforgettable packaging.

Most people need clarification on this term and a search to see if cardboard material is made of paper. Yes, it is made of paper but not the same as normal paper. It is a type of paper product that is thicker and more rigid than standard paper. This flexible material is versatile enough to be cut and folded into different shapes and sizes to suit the needs of the product. Its manufacturing process includes many steps, beginning with the fibers’ pulping and then through multiple stages of pressing and molding.

Most people need clarification on this term and a search to see if cardboard material is made of paper. Yes, it is made of paper but not the same as normal paper. It is a type of paper product that is thicker and more rigid than standard paper. This flexible material is versatile enough to be cut and folded into different shapes and sizes to suit the needs of the product. Its manufacturing process includes many steps, beginning with the fibers’ pulping and then through multiple stages of pressing and molding.

Paperboard is constructed by layering pulp and spraying water onto a mesh screen to create a mat. This process builds up the pulp fibers, strengthening the paperboard. Each grade of paperboard is carefully blended to meet specific standards.

Once the mat is formed, excess water must be removed. Initially, 20% of the water drips through gravity as the mat passes over a foundation screen. The mat then moves through sponge rollers to press and squeeze out water further. The mat is stretched and heated to complete the drying process, reducing the moisture content to 5%.

The dried paperboard is then cut into various widths and rolled into large rolls for transportation to box manufacturers. These widths enable the production of boxes in multiple sizes, shapes, and configurations to meet customer requirements.

After the layers of cardboard are assembled, they undergo a crucial step known as bonding and drying. This process is essential for ensuring that the layers firmly adhere to each other and that any excess moisture is eliminated.

First, the assembled cardboard passes through a series of heated rollers or drying chambers. These rollers or chambers provide controlled heat, which activates the adhesive properties of the materials used in the cardboard layers. As a result, the layers bond securely, forming a unified and sturdy structure.

Additionally, the heat applied during this process evaporates any remaining moisture in the cardboard. Excess humidity can weaken the cardboard and compromise its structural integrity. Removing this moisture makes the cardboard stronger, more rigid, and better suited for its intended purpose.

Overall, the bonding and drying stages are crucial for ensuring that the cardboard is of high quality and ready for further processing or packaging. It plays a vital role in creating cardboard products that are durable, reliable, and able to withstand the rigors of transportation and handling.

The end of this process is to assemble the sheets of cardboard paperboard into the desired shapes and sizes of boxes for the intended use. It may include cutting, scoring, creasing to make folds easy, and printing to make the boxes attractive.